Stop - the braking news on squealing, stretching and leaking

08.01.2024

At Coh&Co we believe that riding a bike is one of life’s elixirs, capable of transforming any day into a more rewarding experience. As great as it is to soar through city streets, an urban bike needs to be able to stop suddenly when one day a kid runs out in front of you, or a distracted motorist cuts you off as they make a last second right turn without signalling. Bicycle brakes are probably the most important performance feature of a bicycle.

In addition to providing optimal braking performance, urban bicycles also need to have a braking system that can survive months worth of road grime, daily use, rain and loads of neglect… While squealing or rubbing brakes, and brakes that lock-up too suddenly, or feel too squishy may be annoying they must be able to stop the bike! There is nothing more dangerous than not being able to stop when needed.

Rim or disc

Traditional rim brakes were once the unrivalled king of bike brake technology, but lets face it there is a lot to be said for disc brakes. Properly tuned and installed, a decent set of disc brakes will perform better – at least in wet conditions while sparring your rims from being chewed up alive by road grime, salt, sand and the brakes themselves. Rim brakes can work great but it is nice to not worry about your rims being a disposable service item and knowing that with 6 screws (yes, yes Shimano or a center lock spline) you can replace a rotor in a matter of a minute or two.

At Coh&Co all of our bicycles are disc brake offerings but that is not the end of the story. Disc brakes in and of themselves come in many different shapes, standards and sizes, and while I am not going to enter into a discussion on mounting standards or brake pad composition – I would like to take a look at some of the points that can help us to understand what options are out there and what to be aware of when looking at a braking system. There is a broad range of options out there and we use some pretty unique gear that we are proud of.

Hydraulic

Many people associate disc brakes with being hydraulic but that does not have to be the case. Disc brakes can be found in hydraulic versions and mechanical versions alike and although not nearly as common, they are also available in a mechanically/cable actuated hydraulic variety. In addition to actuation it is also important to take note that disc brakes are available with both single and double pad actuation. Single actuated calipers engage the one side and deflect the disk until it engages the caliper on the other side. Double acting calipers engage the pad from both sides and provide a cleaner clamping action. Although both systems work, double actions systems are clearly a better choice.

Hydraulic brakes are celebrated for their high-performance braking, providing smooth feel and plenty of stopping power thus enhancing control, particularly in challenging terrains. Hydraulic systems are more complex to install and service and it is the extra labor that usually makes them more expensive. At first glance they may require less maintenance compared to cable actuated systems. However, if a hydraulic hose on an urban bike fails because kids have been yanking on it, or it got snagged on something in a crowded bike parking facility, you risk a leaky brake line and that means that they can lose their ability to engage the brake. The complexity of hydraulic brakes may pose challenges for those less experienced in bike repair and maintenance.

Mechanical brakes are the most common alternative brake calipers available after hydraulic calipers. A double action mechanical brake system can be quite good and although a good set of cables will greatly improve its braking power it will not approach the satisfying feel of a well serviced hydraulic brake.

Now we get to my favourite. At Coh&Co we use mechanical/cable actuated, double or quadruple piston, hydraulic calipers wherever we can. These Hydro-Mechanical wonders provide fantastic clamping power that can stop one of our fully loaded VeloSleds at a moment’s notice and they do so with almost the same great “feel” you get out of a good set of classical hydraulics. The advantage is that they will never require bleeding and are not at risk for catastrophic failure in the usual scenario of chronic neglect and abuse of everyday urban life. Cables are easy to service on the fly with a simple inline cable barrel adjuster and can be replaced on the fly if you are touring on a long trip or over a weekend outing.

Below is a picture of a Yokozuna cable actuated Hydraulic brake with a quality heat dissipating rotor (the black panel in the rotors are heat sinks to get rid of all that energy from braking on steep declines)

Many brakes, especially road bike and gravel bike brakes are defined by the groupset being provided by the manufacturer. If you are looking for a specific groupset with a specific set of drop bar shifters for a drop bar set up, then your brakes system may well be defined by the “brifter” that is used in that groupset. For example Shimano’s successful GRX gravel bike groupsets only afford you the option of hydraulic brakes. If, for whatever reason, you would like to run mechanical disc brakes or mechanically actuated hydraulic brakes, then you’ll find yourself choosing a different groupset – or at least shifters.

For us this is not much of an issue because the majority of our bikes at Coh&Co are flat bar and the drop bar models we do have are cable actuated, often utilizing cable actuated hydraulic brakes.

Cable types

Brake cables may seem like one of the less interesting pieces of kit on your bike, but truth be told they are probably one of the easiest and most noticeable brake performance upgrades out there. These days at Coh&Co we use premium low stretch cables and compressionless housings for all of our brake installations. Should you be riding something else, and if you think your mechanically actuated brakes are well maintained but still feel mushy – then we can promise you that you will be very pleasantly surprised by changing cables and housings to compacted low stretch slick inners w/ compressionless housings.

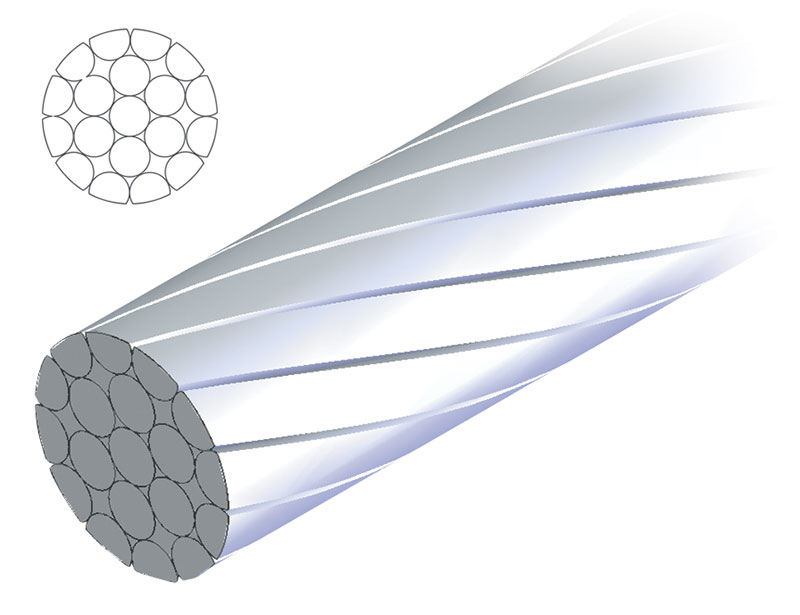

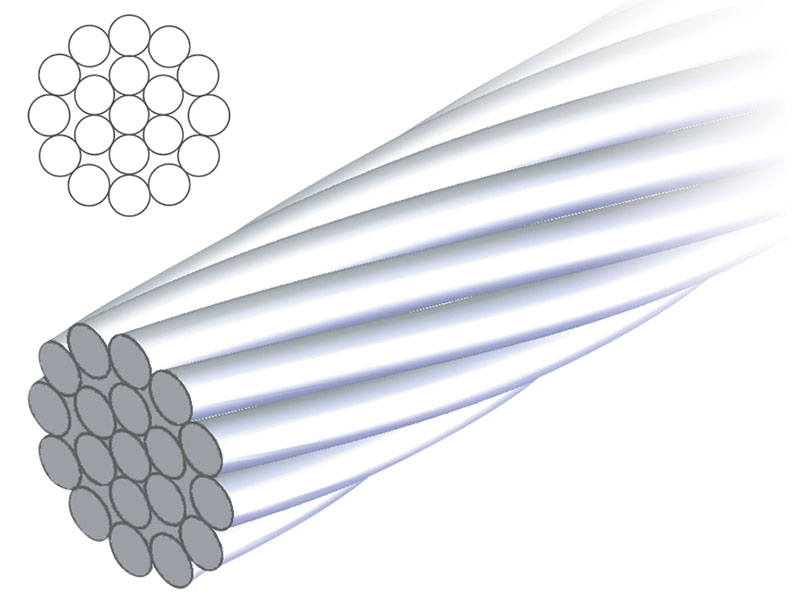

Below are two of Jagwire’s illustrations (checkout jagwire.com to see their line up) and they do a great job of explaining some of the differences between premium brake wire construction, and traditional 1*19 bicycle brake wire construction.

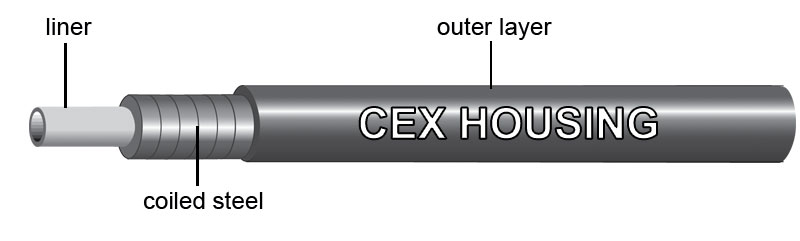

While both construction styles may be composed of the same materials the compacted/low stretch upgrade has several advantages and you will be surprised how big the performance difference can be when using low stretch cables in combination with compressionless housings as opposed to less expensive standard 1*19 cables with the classical, unsupported, coiled steel housings.

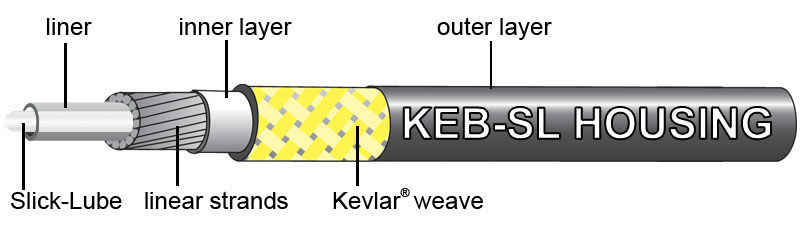

Wire construction does not stand alone. Bowden cables, as brake and shifter control systems are called, do their job as the result of the cable housing working together with the internal control cable; where the cable is in tension the housing is in compression. Housings are to be found in many different configurations. Compressionless housings offer the best brake performance and feel, but they need to be used together with good high quality low stretch cables in order to get an optimum installation. Once again it’s worth checking out the material available online from Jagwire.com or Elvedes.nl.

Size does matter & bigger is better!

Rotor size/diameter is also a variable you don’t think of every day. Rotors range in diameter from Ø140mm to Ø220mm. Obviously the bigger the diameter the more “stopping leverage” the brake will have and better it will be a stopping the wheel from rotating. Bigger rotors also offer better heat dissipation and cooling. We use Ø160mm rotors on most of our bikes. I have mentioned cooling a couple of times now and it must be said that descending down long steep grades in the mountains with disc brakes can really build up a huge amount of heat, potentially damaging the brake and destroying the rotor and the pads. Most good brakes have heat dissipation designed into them and have been tested at high temperatures. Likewise good rotors are not just stainless steel plates but they incorporate aluminum heat dissipation fins to help them get rid of all of that excess braking energy.

Serviceability considerations

Brake actuation mechanism serviceability is pretty straight forward when discussing disc brakes. Where well-bled hydraulic brakes may provide a very reliable, zero maintenance life for long periods at a time they are at risk of losing all braking power if a hydraulic line is damaged; cable actuated brakes may need periodic small adjustments with a barrel adjuster but the chance of breaking a cable is pretty small. In the urban environment the risk is pretty low but there is a very high level of neglect, whereas bike-packing and distance riding serviceability becomes a big issue and carrying an extra set of cables and an extra housing is a very easy solution instead of having to carry brake fluid (haven’t even touched on that) and a bleeding kit to be self sufficient. Either way make sure you have a couple of extra pads if you’re away for extended periods and give those barrel adjusters a turn in or out to optimize your brake performance on a cable actuated system. Clean with Methylated spirits or isopropyl alcohol.

Siggi and Folding Bikes

I am not going to fall into the trap of discussing what other bicycle manufacturers do, but as far as Coh&Co is concerned, we do not fit hydraulic brakes on our Siggi folding bike. We believe that repetitive folding of hydraulic lines and the risk of getting snagged on something when being folded and stored disqualifies hydraulic actuated disc brakes from use in a folding bike. Cable brake systems are much more robust in this regard and much easier to service and maintain should things go wrong.

SQUEALING!

Noisy disc brakes on a bicycle can be attributed to various factors, and contamination of the rotor or brake pads is a common cause. Here are some reasons why disc brakes might make noise:

- Contaminated Rotors or Pads: Oils, greases, or other contaminants can get onto the brake rotors or pads, affecting their performance and causing noise.

- Brake Pad Glazing: Over time, brake pads can become glazed due to excessive heat. This can reduce their effectiveness and lead to noise during braking.

- Misalignment: If the brake calipers or rotors are not properly aligned, it can result in uneven contact and cause noise.

- Worn Brake Pads or Rotors: As brake pads and rotors wear down, they may develop irregularities that can lead to noise.

- Resonance: Some disc brake setups are more prone to resonant vibrations, especially if not properly damped.

- Poor Bedding-in: Properly bedding in new brake pads and rotors is crucial. Inadequate bedding-in can result in noise issues.

Be careful with spray lubricants!

It’s essential to be cautious, especially around disc brakes. Overspray or direct contact with lubricants on the rotor or brake pads can lead to contamination, severely reducing braking performance and causing noise. If your brake pads get contaminated, replacement is the most straightforward solution. Regular maintenance, cleaning, and proper installation can help prevent or alleviate disc brake noise issues. If the problem persists then it’s best to swing by a good mechanic and let them take a look at it.

Feel the great braking performance of disc brakes with this week’s Tuesday Deal on a limited snow-white VeloSled eFamily. Click the button below to learn more.