"So, what's the deal with the rubber band?"

13.11.2023

Belt-driven bicycles often catch people’s attention and spur a bunch of questions. Belts are ideal for urban bikes, internal gear touring bikes, single speeds and fixies: and that is why we choose them whenever we believe it makes sense. Despite their many advantages, belts are however often misunderstood. So why would you want to swap out your trusty (remember the “t”) chain and replace it with a belt?

Of belts and chains

First, let’s address the issue of corrosion: Chains rust and keeping them well-lubricated in the daily routine of urban life requires a disciplined soul. Doing so also means a trade-off between spending some time hassling with a chain guard or choosing an “open” system that almost guarantees oil marks on your “drive side” pant leg and shoe. Let’s face it, oily chains are… oily and messy. Belts completely avoid the issue because they do not require any form of lubrication (99,99% of the time).

There is also the issue of noise; belts just run quieter than a chain. Especially if the chain has not been well lubricated. Silence is golden!

Another, less apparent reason to choose a belt is lifespan. Although a good well-maintained chain should last 5000 kilometres and some will say up to 12000 kilometres (but let’s face it, that is really unusual); a well-adjusted belt should last between 30.000 and 50.000 kilometres. Yes sometimes we have had them blow up after a few months but that is probably more due to a defect or poor adjustment – almost all of the belts we have installed have lasted more or less “forever”.

Now, let’s take a look at what the belt is and what its strengths and weaknesses are. I am sure there are some readers that will immediately say, “hey you forgot to mention… or…”, but I will try to cover the remainder of the good arguments in the text below without getting too detailed or technical.

Gates Carbon Belts

First off, it must be said that we are pretty loyal to our belt supplier. At Coh&Co we have chosen to work with Gates and we believe their products are light years ahead of their competitors. Putting a belt on a drivetrain for a bicycle is not a new idea; actually, there is an American patent for it that was awarded in 1890. In the early 1900s belt drive systems were used on various motorcycles. However, it wasn’t until around 1980 that the technology of the belt-driven drivetrain really began to take off. That was when Gates introduced their first belt modern drive solutions for motorcycles. Since then they have innovated one-piece/continuous belts with fibre-reinforced cores. The belts have gotten narrower. They patented the Centerline belt and cog geometry. Tooth pitch has been optimised to minimise the need for belt tension while reducing slip. Most important of all is that in 2006 they introduced the use of Carbon Fibre as a reinforcement.

So what does this all mean?

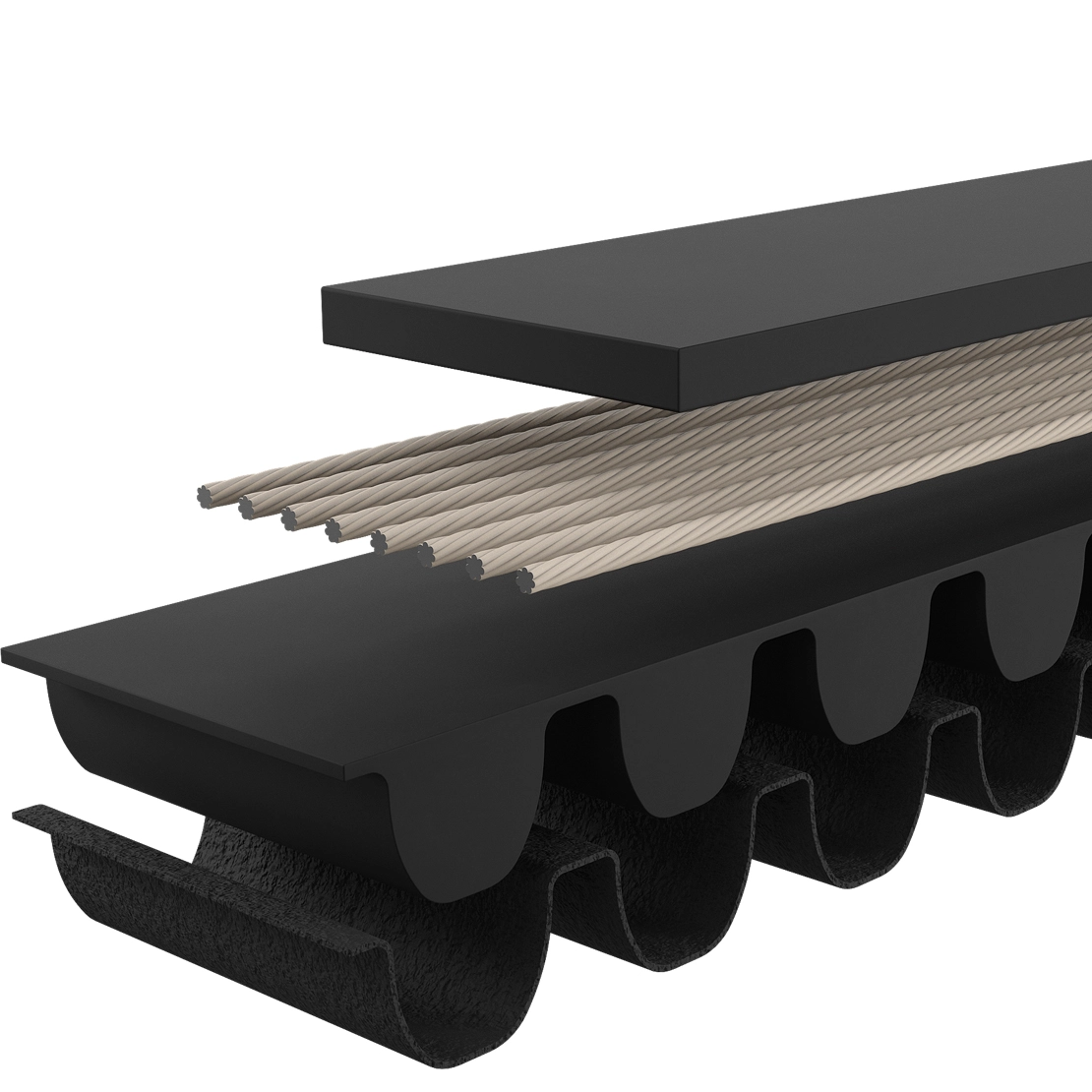

Carbon Fibre: At the surface, a belt looks like a toothed rubber band that engages with cogs at the front and rear of its run. Knowing what we learnt about playing with rubber bands as kids we assume that these belts are elastic and fragile, but the truth of the matter is far from the case. Gates carbon drive belts are actually continuous tows of carbon fibre wound around the design axis of the belt. Carbon fibre is several times the strength of steel and also considerably stiffer while weighing a fraction of what steel weighs. Gates takes this super fibre and encapsulates it in a sheath with super tough teeth on the inside and a protective hide on the outside. Sometimes we get asked if a belt is strong enough and the answer is definitely, “YES”. Let’s face it, this technology has been proven on 150 horsepower motorcycle drivetrains, and that is much more demanding than the approximately 0,5 horsepower that an average well-trained cyclist can keep producing over a 5-minute period.

CenterTrack

Yet another fantastic innovation is “Center Track”. Until 2010 belts ran over cogs with a shoulder to keep them aligned on the cog. This meant not only a heavier wider cog, it also made it hard for dirt and grit to get out of the way and allow the belt and cog to engage. In 2010 CenterTrack was introduced, and now a spline at the centre of the cog meshes with a track in the centre of the belt thus allowing any mud and grime to be flushed out to the side. This improves efficiency while reducing weight and wear and tear.

What's the catch?

At this point, it must be apparent that belts have their place in the greater scheme of things but they do however have their drawbacks. The primary drawback is that if you choose a belt driven Drivechain it won’t be compatible with a good old classic rear derailleur for changing gears. Nope, if you want a belt you can either have internal gears in the hub or at the crank or stick to a single speed. Now although this may be a deal breaker for some people we believe that internal gears and their service-friendly robustness is an ideal compromise for urban bikes. More serious is the issue of belts and rear hub motors because there is only one option. If the motor is in the rear hub and you still need gears then you’ll need to use a gearbox at the cranks. In our case, we have an option of a 3-speed planetary gear at the bottom bracket.

Another issue for some may be that there is a minor loss in efficiency, especially at low speeds, if you need a belt with a lot of tension. There is also a bit of loss in the internal gear hub but let’s face it if you compare this with a chain and external derailleur that hasn’t been oiled in a month or more then you’re ahead of the game.

Some people may argue that another disadvantage of a belt is price, but I would say that considering the longevity of a good belt installation and the reliability and service free nature of the beast there is a lot of value for money.

Finally, there is the issue of frame choice. Belts are continuous and therefore you need to be able to separate the bike’s seatstay from the chainstay to feed the belt into position but at Coh&Co we always use our proprietary modular dropouts and therefore this is never an issue.

CDX, CDC and CDN

Belts are great but they are expensive. Through the years Gates has developed different models for different markets. There are 3 categories in the Gates product line that are central to the Coh&Co market.

Gates divides its product line into different tiers, some would say qualities but since centertrack components are interchangeable we believe this flexibility allows us to combine the ideal combination of performance, robustness and price. We offer CDX / CDC aluminium sprockets in the front and CDC and CDX stainless steel sprockets in the rear. We have really great experience using CDN as our urban belts they are made using the same carbon fibre reinforcement and although they are considered to be lighter duty than their CDC and CDX brethren we have systems with 20 thousand kilometres of urban life (and neglect) and many many kilometres of trekking through the Scandinavian landscape. We do however offer a CDX upgrade on request.

So, I am sure someone reading this has noticed that I wrote that 99,99% of the time belts don’t need lubrication. So what’s the deal with the final 0,001% of the time? Sometimes (especially in temperatures well below freezing) a belt will begin to creak and in that case, a little spritz of Teflon spray will solve the problem…. no oil is needed!

TUESDAY DEAL

Remember that today, November 14th, this fantastic Erik Electric is yours for the low price of 3.560€ or 26.565 DKK (incl. Danish VAT) meaning you save 1,063€ (7.935 DKK) off of the full price (4.623€/34.500 DKK MSRP).

As special add-ons, we’ve included the handy N-lock and a convenient kickstand.

Swing by our showroom in Copenhagen if you want to experience how Erik Electric rides or contact us by clicking the button below to learn more about this great offer.

Check out this week’s Tuesday Deal and get your very own Erik Electric with Belt Drive by clicking the button below